Advanced Laser Technology

Empyrean Laser provides state-of-the-art Laser Cleaning Services for a wide range of applications and industries. Our experienced technicians use advanced laser technology to remove stubborn surface coatings, stains, rust, grease, soot and other types of contaminants quickly and efficiently without damaging the substrate.

Comprehensive Cleaning Solutions

Customized Cleaning for Diverse Needs

Environmentally Friendly Process

Sustainable and Eco-Friendly Practices

Precision Cleaning Results

Achieve Immaculate Surface Finishes

Efficient and Effective Service

Swift Response and Quality Assurance

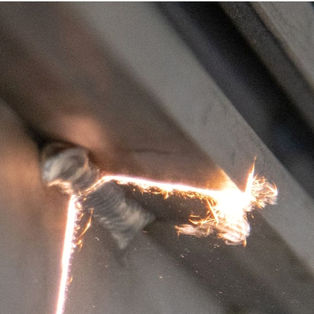

Laser cleaning uses focused light to remove contaminants from the surface of a substrate without damaging the substrate itself. It employs high-energy light pulses to vaporize and remove unwanted surface contaminants. The process is highly precise and controlled, making it efficient in areas where traditional cleaning methods are ineffective or too invasive. Unlike traditional cleaning techniques that leave waste or harmful chemicals, laser cleaning does not generate residues, hazardous materials or spent abrasive mediums.

Our Services

Our mobile laser cleaning service has the advantage of providing the equipment and expertise directly to the site where the material needs to be serviced. This is especially beneficial for situations where transporting the material to a stationary service would be difficult or impractical such as large or immovable objects. It is also a significant cost savings to the client by eliminating shipping or transport expenses.

Surface Cleaning

Precision Cleaning Solutions

We offer precision laser cleaning services designed to remove contaminants from various surfaces such as Wood, Natural Stone, Brick, Masonry, Plaster, Concrete, Stainless Steel, Copper, Aluminum, Machine Steel, Cast Iron, Chrome Coating, Plastics, Tiles, Grout, Ceramics, Silicone, Tapestry and Canvas.

Wood

Safe Solutions For Wood

Laser cleaning is a highly effective and precise method for stripping stains from wood surfaces, offering a revolutionary approach to preserving the original integrity of wooden features. The concentrated laser light selectively evaporates and removes surface stains and coatings without affecting the underlying wood. This targeted approach allows for a controlled and gentle restoration process, minimizing the risk of inadvertently damaging the wood fibers or altering the surface texture.

Stone, Brick, Masonry

Efficient Targeted Cleaning

Indoor and outdoor stone, brick, and masonry features benefit greatly from targeted laser cleaning. Laser cleaning does not require the use of harmful chemicals, and there is no wastewater runoff or blasting media left behind to dispose of once the cleaning process is completed. Any dust generated during the process is cleaned and filtered with our HEPA vacuum and air scrubbers. As a result, the entire process is an eco-friendly clean solution.

Rust Removal

Effective Oxide Removal

Corrosion, rust, and oxides can cause significant damage and reduce the lifespan and performance of equipment and parts. Fortunately, laser rust removal is a faster and more environmentally friendly alternative to traditional methods like sandblasting and chemical removal. It completely removes rust and corrosion down to the bare metal without compromising the metal's integrity.

Grease & Oil

Fast & Easy Degreasing

Traditional methods of targeting grease and oil for cleaning have been expensive, messy, and time-consuming. Degreasing any surface is now fast and efficient. The contaminated layer absorbs the energy of the laser beam and evaporates without causing damage to the substrate.

NDT Preparation

Non-Destructive Testing Preparation

During shutdowns and scheduled inspections of plants, equipment, and assets, the surface preparation for Non-DestructiveTesting (NDT) can greatly benefit from the meticulous and thorough process of laser cleaning. Unlike other methods, laser cleaning ensures that there is no smearing, folding, or alteration to the substrate's surface. It effectively vaporizes surface contamination and eliminates particulates from defects, resulting in an optimal surface condition for dye penetrant and magnetic particle testing.

Our Expertise

Empyrean Laser is dedicated to operating at the highest standard for industrial and commercial cleaning with our innovative laser technology. Our commitment to quality, precision, and sustainable practices distinguishes us as a leader in the laser cleaning industry. With a team of skilled professionals, we continue to explore new possibilities in surface cleaning.

The laser beam can be adjusted to different sizes and intensities, making it useful in cleaning many types of materials. A main advantage of laser cleaning is that it is non-contact. The nozzle does not touch the treated surface. Traditional cleaning methods such as sandblasting or chemical cleaning often cause surface damage or substrate distortion, stressing the material and reducing its lifespan. Laser cleaning is a gentle technique that does not damage the surface, making it suitable for cleaning a wide range of materials from natural stone and wood to delicate metals.